Sacrificial Anode Project

We hypothesize that corrosion of steel building materials may be measurably reduced by gradually inducing other sacrificial materials in the construction process.

Project Overview

Project Goal

Double Black Construction undertook this experimental development project in 2022 to test the benefits of deploying sacrificial anodes to inhibit corrosion on steel construction materials. Our goal is to develop unique technologies and processes which will, if successful, improve the quality of steel used in commercial and industrial constriction and extend the lifespan of outdoor metal structures provided by all manufacturers and suppliers within the industry.

The Problem

We’re Solving

Corrosion is a problem that arises during all phases of steel structure construction and delivery. Between shipping through multiple distribution facilities, storage and erection at construction site, the steel’s protective coating often suffers minor damage which allows corrosion to begin. It can then spread quickly across the entire structure of steel and other building materials. Our objective is to reduce corrosion and extend the lifespan and durability of steel and its incorporated structure.

Our Hypothesis

Our experimental team thinks it may be possible to inhibit corrosion in steel structures by introducing sacrificial anodes at several points in the distribution and building process.

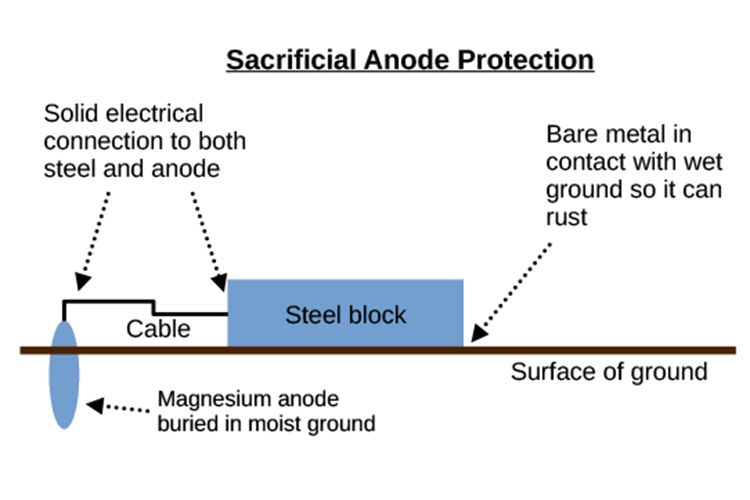

By placing sacrificial material with higher reactivity (specifically, a more negative anodic index) in direct contact with the steel building material, the material could corrode in place of the steel. Building material depreciation may then be measurably reduced by inducing the gradual corrosion of this sacrificial material. Magnesium, zinc or aluminum placed in direct electrical contact with the vulnerable steel could result in beneficial improvement for the structure’s lifespan.

Our Experiment

Double Black Construction has implemented two different experiments using multiple samples of steel I-beams, which are identical to those used in steel construction except that they are shorter. Our first experiment is located in Vancouver, B.C. and the second is located in Thorndale, Ontario.

Each experiment includes using sacrificial anodes in combination with different variations:

- Unpainted undamaged steel I-beam with a magnesium sacrificial anode versus baseline unpainted undamaged steel with no anode.

- Unpainted intentionally damaged steel I-beam with a magnesium sacrificial anode versus baseline unpainted intentionally damaged steel with no anode.

Our Progress

The team is currently measuring the results of corrosion using a variety of techniques and will be sharing the progress on this page. Please bookmark this page and visit us for data updates and results.

Proud Member

Cost-Effective & Reliable

Contact us for a free quote & preliminary drawings.

Location

201 - 30610 Progressive Way

Abbotsford, B.C. V2T 6Z2 Canada

info@DoubleBlackConstruction.com

Call

833-322-2722

Navigation:

Our Focused Services:

Working hours (Pacific Standard)

- Mon - Fri

- -

- Sat - Sun

- Appointment Only

All Rights Reserved | Double Black Construction, 2023.